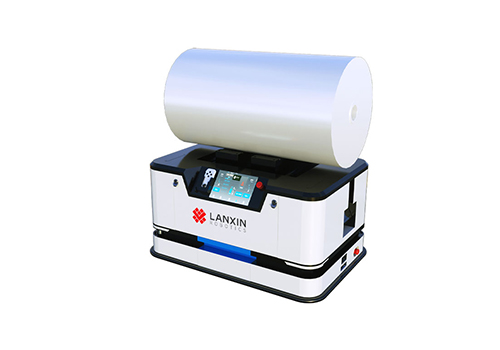

LXLR-FR3300L

Lanxin Technology is a leading provider of industrial robots and intelligent logistics solutions based on deep vision systems in China.

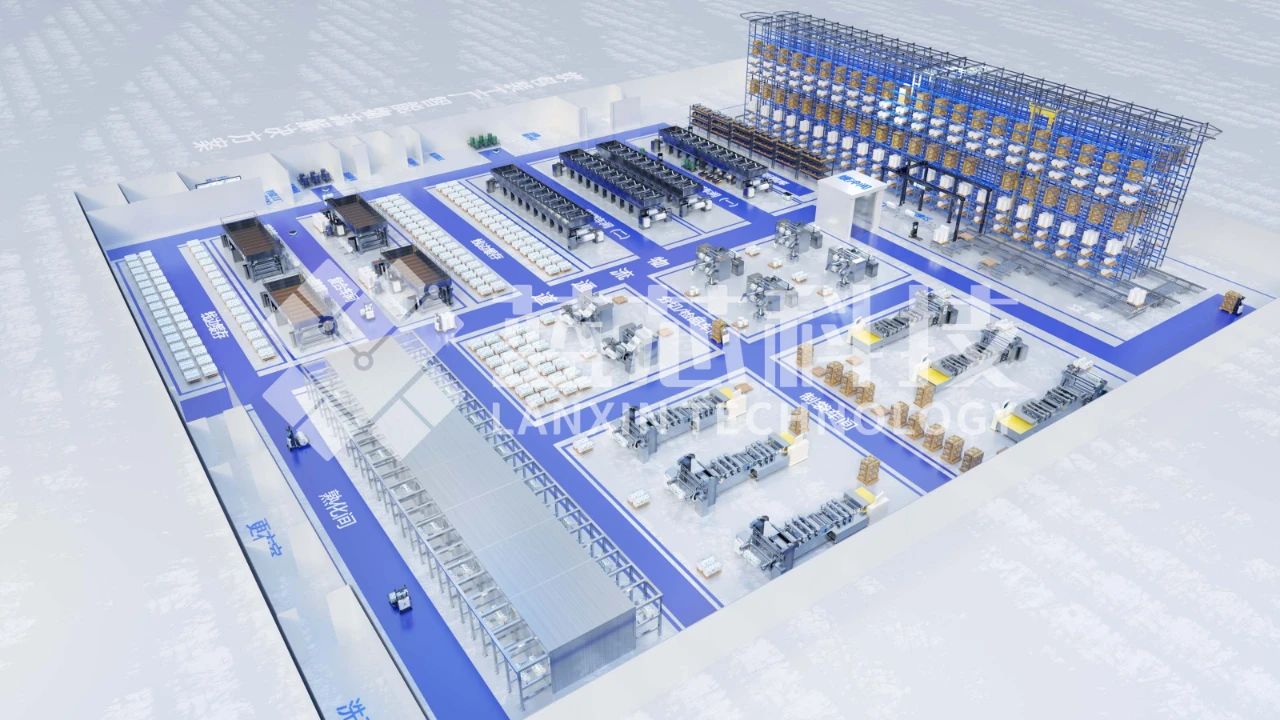

For the printing and packaging industry, Lanxin Technology has introduced intelligent unpacking, horizontal vision robotic arms, printing/coating reel material loading and unloading robots, unmanned handling/pushing high forklifts, back-loading robots, cutting and stacking automatic lines, and other products. The company has also introduced intelligent warehouse equipment, combining it with independently developed information systems to create comprehensive intelligent logistics solutions tailored for the printing and packaging industry.

Key advantages of the solution include:

1. Intelligent factory overall planning: Integrating systems/logistics/warehousing to achieve high automation and informatization.

2. Reduced labor intensity: Decreasing labor for logistics handling; mitigating physical labor intensity.

3. Improved workshop cleanliness: Substituting robots for manual labor to reduce environmental pollution caused by humans.

4. Accident prevention: Replacing manual labor with robots to avoid production accidents caused by human errors.

5. Intelligent warehouse management: Addressing issues related to raw materials, storage locations, and automatic in/out warehousing.

6. Compliance with national policies: Creating smart factories to align with the transformation towards automation, informatization, and intelligence.

Lanxin Technology has closely collaborated with several equipment manufacturers in the printing and packaging industry, such as Hangzhou Shuchuang, Aerospace Huayang, Shaanxi Beiren, and Megmech, to enhance industry equipment intelligence. Additionally, the company has participated in the planning and construction of smart factories/digital factory projects for various leading companies in the printing and packaging industry, contributing to the digital and intelligent transformation of traditional manufacturing.

Case Studies: Transforming Printing Equipment Manufacturing and Soft Packaging Companies

1. Leading Printing Equipment Manufacturer

- Lanxin Technology provided printing/coating reel material loading and unloading robots for a major printing equipment manufacturer in China.

- Results: The deployment of intelligent logistics robots replaced manual forklifts, reducing labor intensity, increasing efficiency, and preventing work-related injuries.

2. Zhejiang Soft Packaging Company

- Lanxin Technology offered intelligent handling solutions for various processes, including unpacking, printing, composite workshops, curing rooms, and temporary storage areas, for a specialized soft packaging company in Zhejiang.

- Results: The project created a model for smart factories/digital factories, driving the transformation and upgrading of traditional manufacturing. Intelligent logistics significantly reduced the need for manual handling personnel, increased production efficiency, and lowered costs for the company.

Lanxin Technology is committed to its mission of "enabling robots to 'understand' the world and serve the world." By focusing on the development of deep vision systems for mobile robots, the company aims to make robots smarter, production more efficient, and contribute to the automation, informatization, and intelligence of the printing and packaging industry.

Contact Us

Lanxin Technology, 7-802,

China Artificial Intelligence Town,

No.1818-2 Wenyi West Road,

Hangzhou, Zhejiang, China

marketing@lanxincn.com

Pouplar Products

Cases